Jun 6th 2023

The Labor Shortage Will Be With Us For A While: Demographics Are Destiny

The COVID-19 pandemic has brought unprecedented challenges to various aspects of our lives, including the economy. One area that has been significantly affected is the manufacturing industry, which is now facing a labor shortage that may span generations. Here we explore the connection between the Census Bureau's population estimates, the impact of COVID-19 on fertility and mortality rates, and the potential consequences for the manufacturing labor force.

The Demographic Shift

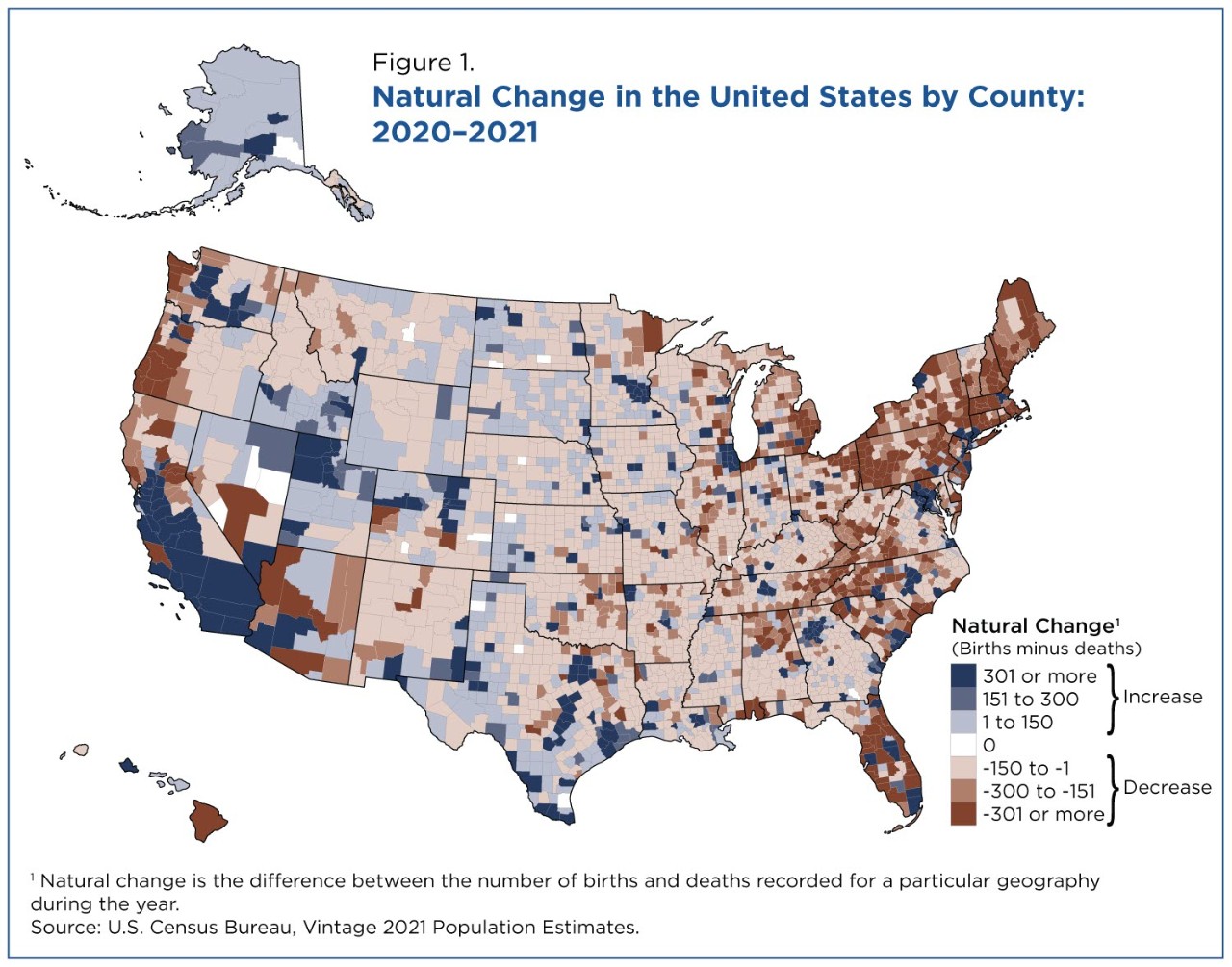

The Census Bureau's population estimates reveal intriguing trends in fertility and mortality rates across the nation. The COVID-19 pandemic has led to a decline in birth rates due to factors such as economic uncertainties, healthcare concerns, and lifestyle changes. This decline in fertility rates suggests a shrinking pool of potential future manufacturing workers.

Additionally, the pandemic has tragically increased mortality rates, primarily among older populations. The loss of experienced individuals within the manufacturing workforce exacerbates the labor shortage issue, as these skilled workers are not easily replaced.

Challenges for the Manufacturing Industry

The manufacturing industry has always relied on a robust labor force to sustain its operations. However, the combination of reduced fertility rates and increased mortality rates presents a significant challenge. The decline in the number of younger individuals entering the workforce, coupled with the loss of experienced workers, creates a potential shortage of skilled labor within the manufacturing sector.

The Role of Automation

The manufacturing industry, including industrial and CNC machining sectors, has increasingly turned to automation as a means to address the labor shortage issue. With the advancement of technology, automation offers numerous benefits and solutions for manufacturers facing challenges in finding an adequate workforce. One prominent player in the field of automation is Universal Robots, a leading manufacturer of collaborative robots (cobots) for industrial OEM applications.

- Collaborative Robots for Industrial OEM Applications: Universal Robots specializes in developing cobots designed specifically for industrial OEM applications, including CNC machining and other manufacturing processes. These robots are equipped with advanced sensors and safety features that enable them to operate safely in close proximity to human workers. They can assist with various tasks, such as CNC machining operations, assembly, pick-and-place tasks, packaging, and quality control in the manufacturing industry.

- Increased Productivity and Efficiency in CNC Machining: Automation through cobots from Universal Robots enhances productivity and efficiency in CNC machining processes. These robots can handle repetitive and time-consuming tasks in CNC machining, such as loading and unloading workpieces, tool changes, and quality inspection. By automating certain aspects of CNC machining, manufacturers can achieve higher efficiency, precision, and output levels, compensating for the shortage of available labor.

- Skill Enhancement and Workforce Optimization: Cobots from Universal Robots are designed to be user-friendly and easily programmable, making it possible for existing workers to quickly learn and operate them. This allows manufacturers in the CNC machining industry to enhance the skills of their workforce and optimize their labor resources. Human workers can focus on more complex CNC machining operations, programming, and quality assurance, while the cobots handle repetitive tasks.

- Flexibility and Adaptability in CNC Machining: Universal Robots' cobots are known for their flexibility and adaptability in CNC machining. They can be easily programmed and reprogrammed to perform specific CNC machining tasks, such as milling, turning, or drilling, according to changing production requirements. Manufacturers can integrate cobots into their CNC machining workflows, maximizing their productivity and adapting to varying workloads or product demands.

- Cost-Effectiveness and Affordability for CNC Machining OEMs: Compared to traditional industrial robots, cobots from Universal Robots are often more cost-effective and affordable for CNC machining OEMs. They have a lower initial investment cost, require less space, and can be easily reprogrammed without extensive downtime. This affordability makes automation accessible to a wider range of CNC machining OEMs, including small and medium-sized enterprises (SMEs).

- Worker Safety in CNC Machining: Universal Robots places a strong emphasis on worker safety in CNC machining and industrial OEM applications. Their cobots are equipped with advanced safety features, such as force sensing and collision detection, ensuring safe operation alongside human workers in CNC machining environments. This focus on worker safety ensures a secure working environment, reducing the risk of accidents and injuries in the CNC machining industry.

In summary, Universal Robots and their collaborative robots have played a significant role in the manufacturing industry's turn towards automation to address labor shortages, particularly in CNC machining and industrial OEM applications. Their user-friendly interface, flexibility, cost-effectiveness, and focus on worker safety make them valuable assets for CNC machining OEMs looking to optimize productivity, enhance skills, and fill the gaps created by labor shortages.

Have You Calculated Your Opportunity Cost of Waiting To Deploy Your Next Automation Project? Calculate your ROI on a collaborative robot investment at https://roi.automationdistribution.com/.

Implications for Economic Growth

A manufacturing labor shortage has broader implications for economic growth. The manufacturing sector plays a vital role in driving innovation, generating employment opportunities, and contributing to national GDP. A shortage of skilled labor can hinder the industry's ability to meet production demands, leading to delays, reduced competitiveness, and potential outsourcing to other countries. This can have a ripple effect on related industries and the overall economy.

Addressing the Labor Shortage

To address the potential manufacturing labor shortage, a multi-faceted approach is required. Firstly, investments in education and vocational training should be prioritized to develop a skilled workforce. Collaborations between educational institutions and the manufacturing sector can help bridge the skills gap and attract more individuals to pursue careers in manufacturing.

Additionally, policies aimed at supporting working parents, such as affordable childcare and flexible work arrangements, can help mitigate the decline in fertility rates and encourage individuals to remain in or re-enter the workforce.

The COVID-19 pandemic has had far-reaching effects on society and the economy, and the manufacturing industry is not exempt. The Census Bureau's population estimates, reflecting shifts in fertility and mortality rates, highlight the potential labor shortage in manufacturing. By recognizing these demographic changes and implementing proactive measures, such as investing in education and supporting working parents, we can work towards ensuring a sustainable and thriving manufacturing labor force for the future.

Sources: https://www.census.gov/library/stories/2022/03/dea... ChatGPT