Universal Robots Case Study: Johnson & Johnson’s Assembly Line

Johnson & Johnson’s Greek facility required its employees to do very repetitive, boring work. To relieve employees of these tasks, the company installed Universal Robots collaborative robot technology to increase morale and allow employees to pursue more interesting work at the company.

The robot would have to perform multiple complicated tasks including picking up different types of bottles, transferring them to a packaging machine and sorting them by product type. Johnson & Johnson identified that a flexible robot solution would be required for the task.

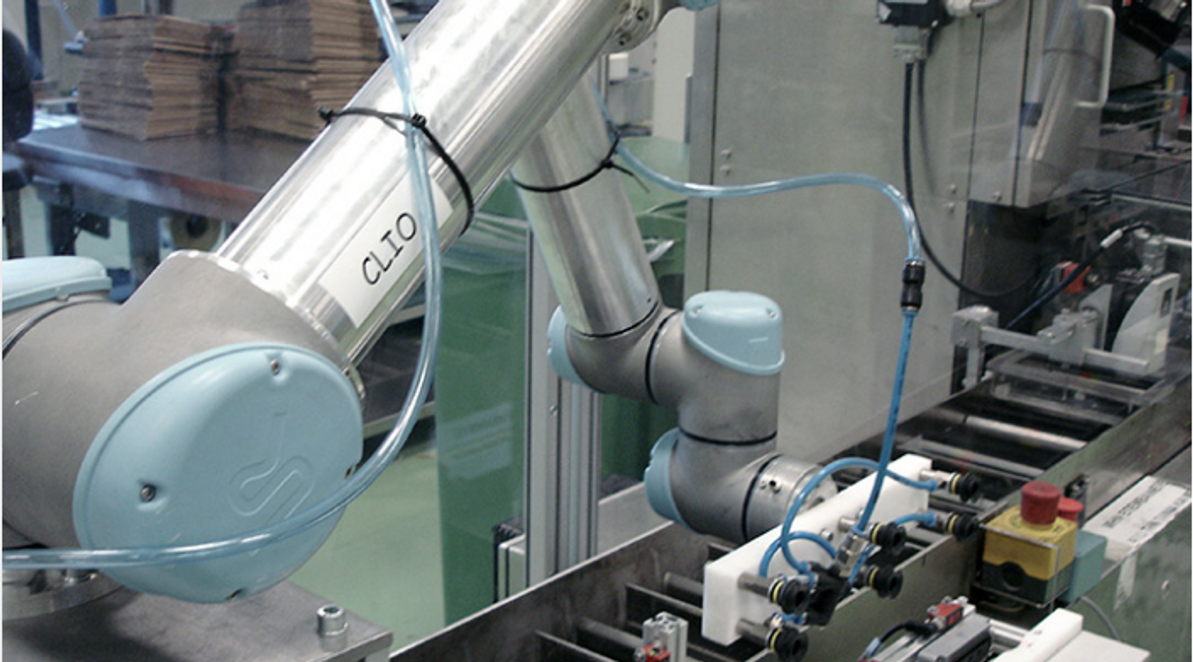

A cage-free Universal Robots arm was determined to be the best solution. After installation, Johnson & Johnson measured that the robot sped up processes by working faster and harder than any human would be able. Additionally, the user-friendly interface enabled employees without much tech savvy could easily operate the robot. Feedback from employees was extremely positive and the collaborative robot became so popular among the employees that they nicknamed it Clio.

“The feedback from Johnson & Johnson is 100% positive. The fact that the employees have named the robot says it all,” said the supplier.

Contact us for a free pick and place Universal Robots demo and calculate your Universal Robots ROI here.

Recent Posts

-

Multinational Pharma Extends Use of Robotiq Palletizing Units

The journey toward improving palletizing efficiencies with one of the world's largest pharmaceutical …Jul 18th 2024 -

Optimize Track and Trace with High-Volume Scanning Solutions

Driving Performance. Leading Solutions. In modern work environments where goals shift rapidly a …Jul 11th 2024 -

The Emergence of the Connected Factory: Digital Revolution in Manufacturing

Manufacturers are facing the resource-intensive route that digital transformation often requires as …Jun 27th 2024