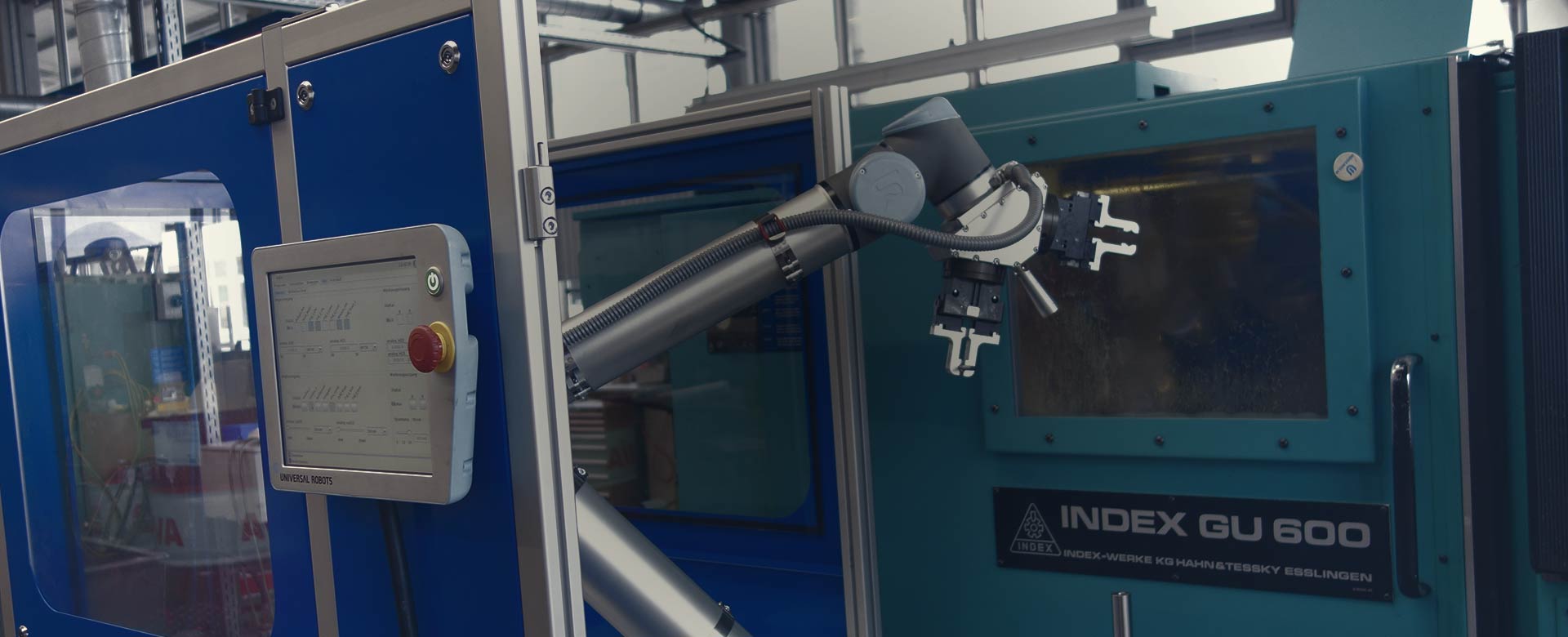

Machine Tending Using Collaborative Robots

Robotic Arms May Be Used for Many Machine Tending Applications

Machine tending can be repetitive and uneventful. A collaborative robot can be used to tend machines and relieve employees of repetitive work – freeing their time to be used to add value to your business. With UR’s fast and flexible deployment, you can quickly adapt production lines to new products. Add value to your business with the collaborative robot arm that pays for itself more quickly than any other robot in the industry.

Improve speed and process quality while reducing the risk of injury associated with working in close proximity to heavy machinery. If the machine tending robot comes into contact with a person, our patented technology limits the forces at contact. UR robots can also be programmed to operate in reduced mode when a human enters the robot’s work area and resume full speed when the person leaves.

Machine tending application - Universal Robots

- Now you can replace human operators in dirty, dangerous and dull jobs to reduce repetitive strain and accidental injuries. Most of the collaborative robots that we have installed worldwide operate with no safety guarding (after risk assessment), right beside human operators.

- Expand production capabilities with increase quality, consistency and production speed. The deployment of the robotic arm in new processes is fast and easy, giving you the agility to automate almost any manual task, including those with small batches or fast change-overs. The robot is able to re-use programs for recurrent tasks.

- Lower your operation costs. Universal Robots gives you all the advantages of advanced robotic automation, with none of the traditional added costs associated with robot programming, set-up, and dedicated, shielded work cells. The average payback period of 195 days is the fastest in the robot industry.

- The UR robot can be used to run most machine tending applications automatically. The space-saving robot can also be reprogrammed quickly and used with different machines. It is the perfect choice for small-volume productions or changing workflows and operational set-ups. Robot extensions can be customized to the manufacturing requirements.

- Universal Robots robot arms are IP-54 certified and need additional protection when working in corrosive liquid environments.