Application

Parcel Induction Quality Control

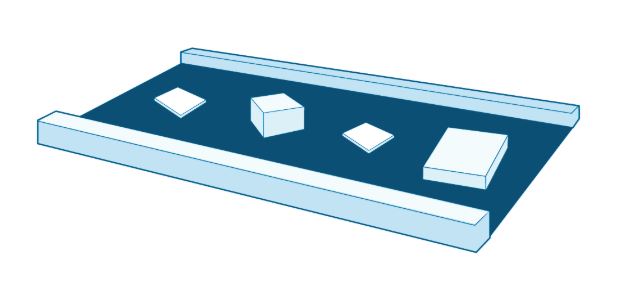

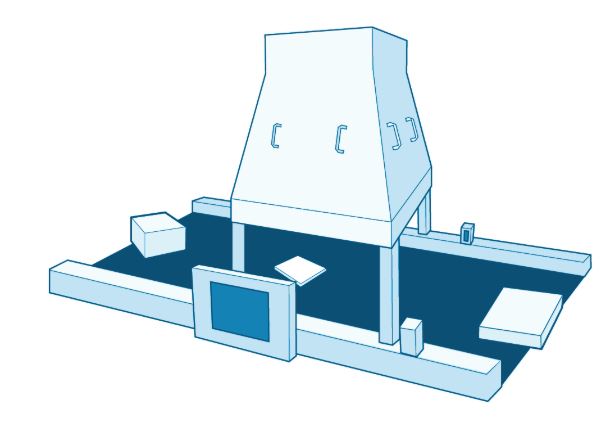

CheckOne is a stand-alone real-time quality control system that mounts over standard induction conveyors. It can be installed in less than a day without interrupting normal operation. CheckOne makes it easy to know what is working best.

Problem

Overview

A major e-commerce retailer wanted to increase the quality of their manual-induction process by improving their associate performance at each of the 8 induction lanes of their high speed sorters.

Solution

How it Works

A CheckOne system was installed on each induction lane. Each parcel an associate places flows through the system at 300 fpm. Using 2D, 3D and AI tools, CheckOne determines the dimensions, location on the belt, induction angle, presence and readability of the label, and whether it is a single or multiple-parcel (overlapped). If all parameters are within tolerance, CheckOne provides immediate reinforcement to the operator with a green light. If not, it signals with a red light and sends the parcel to the exception chute to prevent mis-sorts. CheckOne logs and reports performance data to allow managers to make real-time operations decisions.

Contact us for more information.