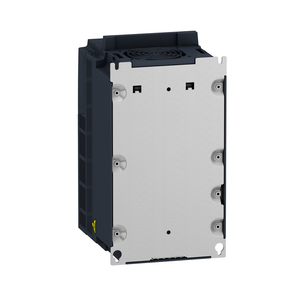

Schneider Electric ATV320U40S6C Atv320 4Kw 600V 3Ph Compact Control Vari

Schneider Electric

$1,188.00

$1200 Minimum Order for Non-stock Items or $60 Addl Schneider Handling Fee Applies

Altivar Machine ATV320 range is an offer of variable speed drives designed for Original Equipment Manufacturers (OEMs). Its compact form factor allows vertical stacking of drives inside machine frames. It works at a rated power up to 4kW / 5hp and a rated voltage from 525V to 600V AC. Its robust design with IEC 60721-3-3 class 3C3 coated printed circuit boards allows to extend machine availability in harsh environmental conditions, for example at ambient temperatures of up to 60°C without the need of additional cooling. It incorporates functions suitable for the most common applications, including torque and speed accuracy at very low speed, high dynamic performance with flux vector control without sensor and extended frequency range for high-speed motors. It also incorporates parallel connection of motors and special drives using the voltage/frequency ratio and static speed accuracy and energy saving for open-loop synchronous motors. It weighs 2.5kg and its dimensions are 140mm wide, 184mm high, 158mm deep. The drive software includes 5 safety functions that help machines meet safety requirements, whether or not they are used in conjunction with a Preventa safety module. These safety functions are configured using SoMove software. Altivar Machine ATV320 was designed for Original Equipment Manufacturers (OEMs) that meets simple and advanced application requirements covered for packaging, material handling, textile, material working, mechanical actuators and hoisting. It conforms to IEC, UL, TUV, KC and other international standards. Mounting accessories and external options (braking resistors, line chokes, motor chokes, additional EMC filters) are available with Altivar Machine ATV320 drives. The type of external accessories and options depends on the drive rating. The product is delivered in three packages. It is designed to be mounted in vertical position (+/- 10 °) on a panel, thanks to 4 fixing holes. It is fully integrated inside Schneider Electric’s EcoStruxure Machine through DTM. It is possible to configure, control, and diagnose ATV320 drives directly in SoMachine and SoMove software by means of the same software brick (DTM). It is eco-friendly and complies with directives such as RoHS, WEEE, etc.relating to environmental protection.

- Communication Port Protocol:

- Modbus serial || CANopen

- Mercury Free:

- Yes

- California Proposition 65:

- WARNING: This product can expose you to chemicals including: Lead and lead compounds, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

- Weee:

- The product must be disposed on European Union markets following specific waste collection and never end up in rubbish bins.

- Product Or Component Type:

- variable speed drive

- Brake Chopper Integrated:

- TRUE

- Power Dissipation In W:

- fan 96.0 W 525 V 4 kHz

- Ambient Air Temperature For Operation:

- -10-50 °C without derating || 50-60 °C with derating factor

- With Safety Function Safe Position (Sp):

- FALSE

- Reach Regulation:

- Reference contains Substances of Very High Concern above the threshold

- Net Weight:

- 2.5 kg

- Product Specific Application:

- complex machines

- Discrete Output Type:

- open collector DQ+ 0-1 kHz 30 V DC 100 mA || open collector DQ- 0-1 kHz 30 V DC 100 mA

- Base Load Current At High Overload:

- 6.1 A

- Speed Accuracy:

- +/- 10 % of nominal slip 0.2 Tn to Tn

- Maximum Acceleration Under Vibrational Stress (During Operation):

- 10 m/s² at 13...200 Hz

- Analogue Input Number:

- 3

- Asynchronous Motor Control Profile:

- voltage/frequency ratio, 5 points || flux vector control without sensor, standard || voltage/frequency ratio - Energy Saving, quadratic U/f || flux vector control without sensor - Energy Saving || voltage/frequency ratio, 2 points

- Rohs Exemption Information:

- Yes

- Nominal Switching Frequency:

- 4 kHz

- With Safety Function Safe Operating Stop (Sos):

- FALSE

- Acceleration And Deceleration Ramps:

- linear || U || S || CUS || ramp switching || acceleration/deceleration ramp adaptation || acceleration/deceleration automatic stop with DC injection

- Option Card:

- communication module, CANopen || communication module, EtherCAT || communication module, Profibus DP V1 || communication module, PROFINET || communication module, Ethernet Powerlink || communication module, EtherNet/IP || communication module, Device

- Motor Slip Compensation:

- automatic whatever the load || adjustable 0...300 % || not available in voltage/frequency ratio (2 or 5 points)

- Standards:

- IEC 61800-5-1

- Circularity Profile:

- ENVEOLI1512005EN

- Marking:

- CE || ATEX || UL || CSA || EAC || RCM

- Overvoltage Category:

- III

- China Rohs Regulation:

- X

- With Safety Function Safely Limited Speed (Sls):

- TRUE

- Minimum Switching Current:

- relay output R1A, R1B, R1C, R2A, R2C 5 mA 24 V DC

- With Safety Function Safe Speed Monitor (Ssm):

- FALSE

- Upgradeability:

- Upgraded components available

- Relay Output Type:

- configurable relay logic R1A 1 NO 100000 cycles || configurable relay logic R1B 1 NC 100000 cycles || configurable relay logic R1C || configurable relay logic R2A 1 NO 100000 cycles || configurable relay logic R2C

- [Us] Rated Supply Voltage:

- 525...600 V - 15...10 %

- Discrete Input Logic:

- positive logic (source) || negative logic (sink)

- Discrete Input Type:

- STO safe torque off, 24 V DC1.5 kOhm || DI1...DI6 logic inputs, 24 V DC 30 V) || DI5 programmable as pulse input 0-30 kHz, 24 V DC 30 V)

- With Sft Fct Safe Stop 2 (Ss2):

- FALSE

- Depth:

- 158.0 mm

- Ambient Air Transport Temperature:

- -25-70 °C

- Network Frequency:

- 50-60 Hz

- Mounting Mode:

- wall mount

- With Safety Function Safe Direction (Sdi):

- FALSE

- Analogue Input Type:

- AI1 voltage 0...10 V DC 30 kOhm 10 bits || AI2 bipolar differential voltage +/- 10 V DC 30 kOhm 10 bits || AI3 current 0...20 mA (or 4-20 mA, x-20 mA, 20-x mA or other patterns by configuration) 250 Ohm 10 bits

- With Safety Function Safe Brake Management (Sbc/Sbt):

- FALSE

- Emc Filter:

- without EMC filter

- Method Of Access:

- slave CANopen

- With Safety Function Safe Programmable Logic:

- FALSE

- Synchronous Motor Control Profile:

- vector control without sensor

- With Safety Function Safe Torque Off (Sto):

- TRUE

- With Safety Function Safely Limited Position (Slp):

- FALSE

- Volume Of Cooling Air:

- 37.7 m3/h

- Regulation Loop:

- adjustable PID regulator

- Electromagnetic Compatibility:

- electrostatic discharge immunity test level 3 IEC 61000-4-2 || radiated radio-frequency electromagnetic field immunity test level 3 IEC 61000-4-3 || electrical fast transient/burst immunity test level 4 IEC 61000-4-4 || 1.2/50 µs - 8/20 µs surge im

- Pollution Degree:

- 2

- Ip Degree Of Protection:

- IP20

- Eu Rohs Directive:

- Pro-active compliance (Product out of EU RoHS legal scope)

- Prospective Line Isc:

- 5 kA

- Protection Type:

- input phase breaks drive || overcurrent between output phases and earth drive || overheating protection drive || short-circuit between motor phases drive || thermal protection drive

- Ambient Air Temperature For Storage:

- -25-70 °C

- Relative Symmetric Network Frequency Tolerance:

- 0.05

- Maximum Output Voltage:

- 600 V

- Discrete Output Number:

- 3

- Variant:

- standard version

- Range Of Product:

- Altivar Machine ATV320

- Format Of The Drive:

- compact

- Discrete Input Number:

- 7

- 4 Quadrant Operation Possible:

- TRUE

- Environmental Class (During Operation):

- class 3C3 according to IEC 60721-3-3 || class 3S2 according to IEC 60721-3-3

- Maximum Output Frequency:

- 0.599 kHz

- Environmental Disclosure:

- ENVPEP1512005EN

- Operating Position:

- vertical +/- 10 degree

- Switching Frequency:

- 2...16 kHz adjustable || 4...16 kHz with derating factor

- Height:

- 184.0 mm

- Nominal Output Current:

- 6.1 A

- Transient Overtorque:

- 170-200 % of nominal motor torque

- With Safety Function Safe Stop 1 (Ss1):

- TRUE

- Sustainable Offer Status:

- Green Premium product

- Analogue Output Type:

- software-configurable current AQ1 0...20 mA 800 Ohm 10 bits || software-configurable voltage AQ1 0...10 V DC 470 Ohm 10 bits

- Permitted Relative Humidity (During Operation):

- class 3K5 according to EN 60721-3

- Maximum Acceleration Under Shock Impact (During Operation):

- 150 m/s² at 11 ms

- Analogue Output Number:

- 1

- Maximum Switching Current:

- relay output R1A, R1B, R1C resistive, cos phi = 1 3 A 250 V AC || relay output R1A, R1B, R1C resistive, cos phi = 1 3 A 30 V DC || relay output R1A, R1B, R1C, R2A, R2C inductive, cos phi = 0.4 7 ms 2 A 250 V AC || relay output R1A, R1B, R1C, R2A, R2C

- Line Current:

- 6.5 A 525 V heavy duty) || 5.8 A 600 V heavy duty)

- Width:

- 140 mm

- Braking To Standstill:

- by DC injection

- Apparent Power:

- 6.0 kVA 600 V heavy duty)

- Motor Power Kw:

- 4.0 kW heavy duty

- Maximum Deflection Under Vibratory Load (During Operation):

- 1.5 mm at 2...13 Hz

- Product Certifications:

- CE || ATEX || NOM || GOST || EAC || RCM || KC

- Brochure:

- View

- Catalog:

- View

- Datasheet:

- View