Are Cobots Really Safe?

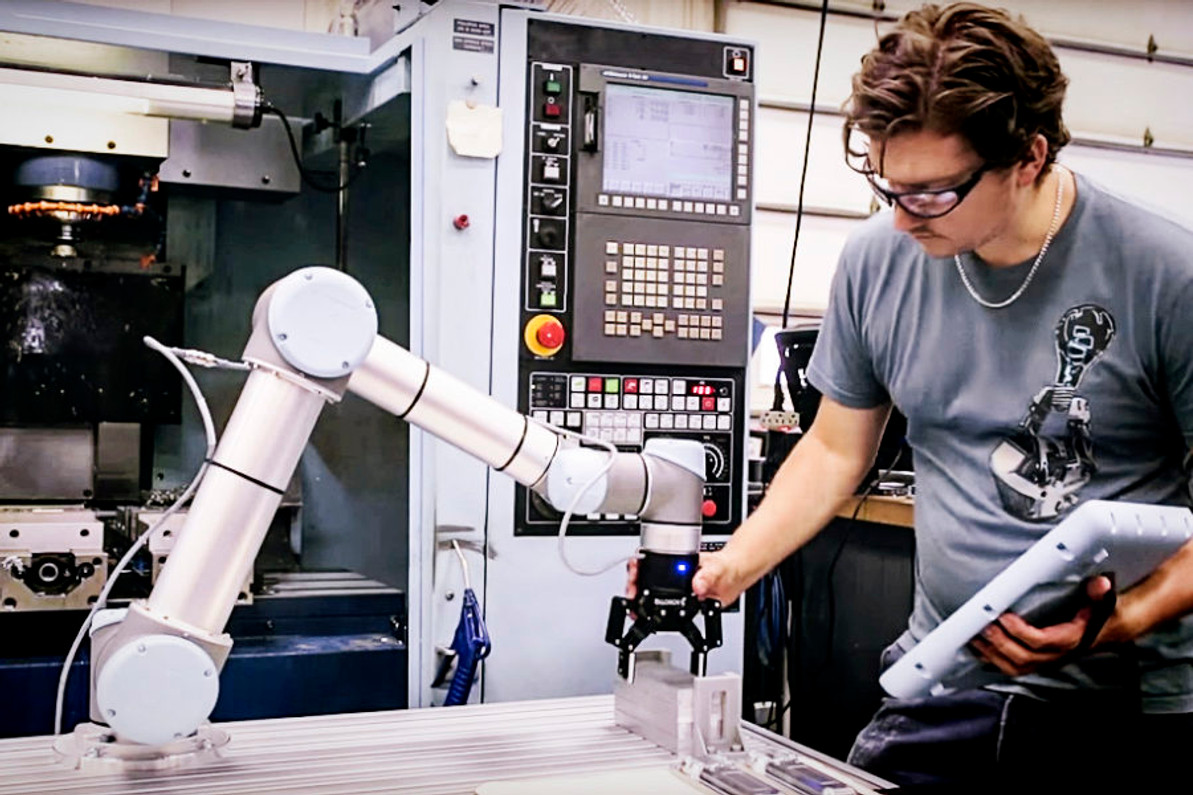

Collaborative robots are promoted as not requiring safety guarding and able to work right alongside human employees. This does not necessarily mean they are inherently safe once deployed with any attachments, such as sharp end-effectors or welding tools. The engineering team must consider the application and the environment when creating and implementing a collaborative robot system.

Two of the most critical safety standards relating to collaborative robot cells are the ISO/TS 15066 and RIA TR 15.606, which address four different types of cobot integrations. Those include safety-rated monitored stop, hand guiding, speed and separation monitoring, and power and force limiting.

Some other helpful standards include UL 1740, ANSI RIA R15.06, CAN/CSA Z434, EN/ISO 10218-1, and EN/ISO 10218-2.

While there are a variety of available operations for which collaborative robots are useful, the most common is the power and force limit utilization where a human may physically interfere with a collaborative robot in motion. All risk assessment should include how the entire collaborative robot workspace is constructed. Access, clearances, end-effectors, and how the human will be using the robot are all important aspects of an accurate safety assessment.

Universal Robots cobots come with a built-in force sensing feature designed to help protect human employees when they are working together. To learn more about collaborative robots and how they can be safety deployed in your application, contact us here.

Recent Posts

-

Using Scan Tunnels to Track, Sort and Route Warehouse Packages

If you’re using conveyor lines to move products, packages and shipments through your warehouse, the …Apr 17th 2024 -

Embracing Collaboration: How Universal Robots Transformed DeAngelo Marine Exhaust

When the welding robots made their debut at DeAngelo Marine Exhaust, there was a mix of excitem …Apr 11th 2024 -

How to Speed Up Your Warehouse Packing by 33% with Machine Vision

Packing benches are some of the busiest areas of most warehouses, with thousands of items to pack i …Apr 4th 2024