Chiller Surge Prevention

Chiller surge occurs when refrigerant rushes backwards from the condenser to the compressor, causing serious damage to the system. As a result, it begins to flow backwards through the discharge line and into the compressor. Because the compressor's purpose is to pump refrigerant into the discharge line and into the condenser, it will continue to revolve. The refrigerant will flow back through the impeller blades and out through the suction line into the evaporator since the pressure is already too high.

The differential between condenser and evaporator refrigerant pressures determines the maximum lift (head pressure) of each chiller system. The difference between the leaving chilled-water temperature (LCHWT) and the incoming condenser-water temperature can also be used to determine lift (ECWT). If the differential rises above the pumping capability of the system, refrigerant will flow backward via the compressor wheel every few seconds. The refrigerant surges forward again as pressure rises in the compressor, and the cycle repeats. The thrust assembly, bearings, and gearbox may be damaged, and the safety disc may burst or the relief valve may blow. Surge is distinguished by a loud, distinct sound that has been compared to an elephant's screech or a surging jet engine, as well as a change in compressor amperage.

Chillers are built to satisfy specific system specifications and operating circumstances. A well selected chiller will not spike with proper maintenance and operation within design purpose. Surges can occur as a result of changes in operating conditions, especially when the load is low. Maintenance difficulties like clogged tubes, low refrigerant charge, or non-condensables in the refrigerant might cause a surge. Poor regulation of water flow rates and condenser water temperatures can also cause it. With hot gas bypass or VFDs, low load (surge) difficulties can be prevented or remedied.

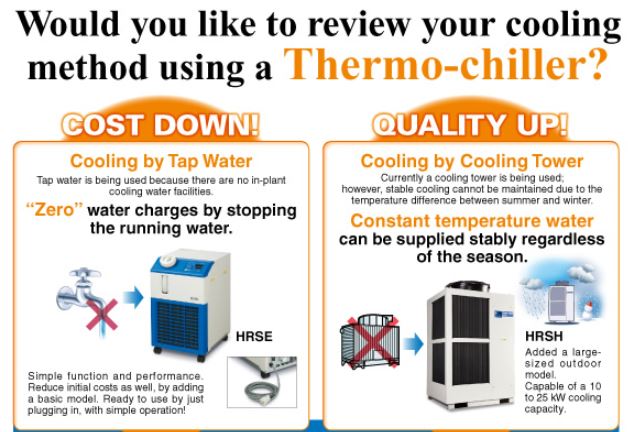

Chiller Evaluation Program - Try Before You Buy

Take one of our chillers for a test drive before committing.

Program Features

- Validate your cooling process

- Evaluate our chiller before purchase

- Variety of styles and capacities

- Over 70 chillers available

- Evaluation period up to 45 days

Our Chiller Advantages

- High quality

- Precision control

- Energy savings

- Global support

Contact us today about the Chiller Evaluation program and prevent unnecessary issues with chiller surge.

Sources: The Engineering Mindset, Mechanical Service Corporation, SMC

Recent Posts

-

Logistics Handling with Schmalz: Vacuum Technology Tailored for a Fast-Moving World

The logistics industry stands as a cornerstone of economic growth. Fueled by globalization and e-com …Apr 24th 2025 -

Baumer’s UF200 and SWIR Cameras Named 2025 Products of the Year

Innovation, precision, and performance—that’s what Baumer delivered in 2025, and the ind …Apr 17th 2025 -

Boost Conveyor Performance with Baumer Sensor Solutions

Conveyors are the backbone of warehouse and distribution center efficiency, seamlessly transpor …Apr 9th 2025