How to Choose Between Cobots and Industrial Robots

When choosing between a collaborative robot and a traditional industrial robot, one must consider all aspects of the application. No one solution is better for all applications.

Advantages and Disadvantages of Robot Types

Cobots offer increased safety and ease of use while traditional robots come with higher speeds and payloads. Cobots use little to no safety cage guarding while traditional robots nearly always do. One advantage of collaborative robots is the availability of integrated force control. While industrial robots may be altered to have this feature, the process can be expensive and arduous. While these may be some primary factors involved in the final selection of a robotic solution, there are other considerations.

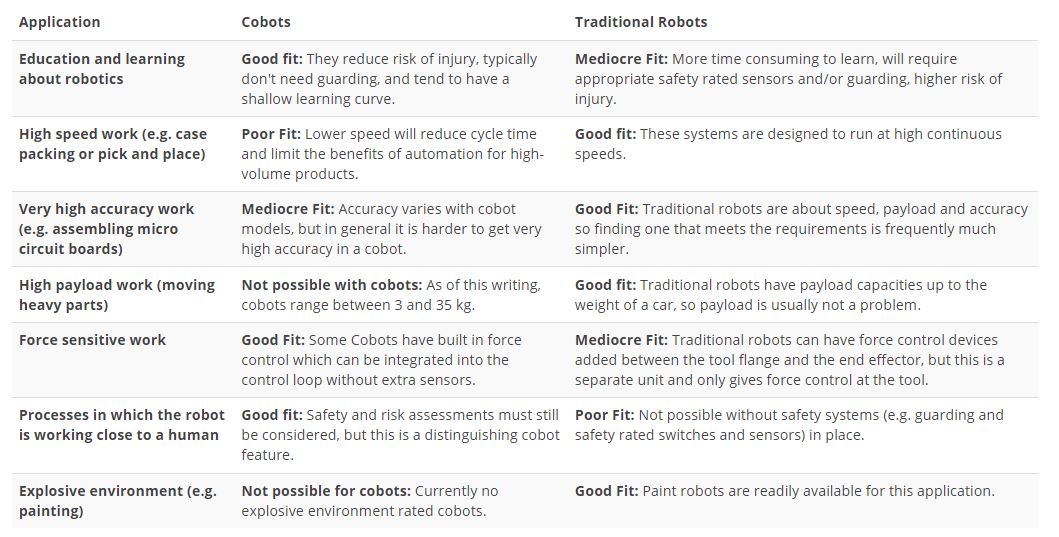

The chart below outlines some supporting applications considerations and can help determine what kind of robot is best for a specific job. Download this table as a starting point in determining if a collaborative robot or traditional robot is the best solution, then contact our specialists at 1-888-600-3080 for a free consultation or request a demo.

Recent Posts

-

Logistics Handling with Schmalz: Vacuum Technology Tailored for a Fast-Moving World

The logistics industry stands as a cornerstone of economic growth. Fueled by globalization and e-com …Apr 24th 2025 -

Baumer’s UF200 and SWIR Cameras Named 2025 Products of the Year

Innovation, precision, and performance—that’s what Baumer delivered in 2025, and the ind …Apr 17th 2025 -

Boost Conveyor Performance with Baumer Sensor Solutions

Conveyors are the backbone of warehouse and distribution center efficiency, seamlessly transpor …Apr 9th 2025