Sweethearts Conversation Hearts Automates to Make Seasonal Demand Efficient

Within an expansive 816,000-square-foot facility, New England Confectionery Co. (NECCO) in Revere, MA, engages in the production of a diverse range of treats, including renowned candy wafers, chocolate bars, thin chocolate mints, and private-label brands. Among its popular offerings are Valentine's Day candies known as Sweethearts Conversation Hearts.

The production of Sweethearts candies exceeds 8 billion annually, with manufacturing taking place from late February to mid-January of the following year. This particular product line typically sells out within six weeks, reflecting its significant demand.

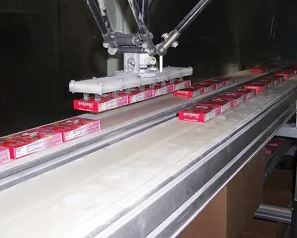

To enhance the efficiency of the Sweethearts' packaging process, the company implemented an automated conveying and picking system. This system incorporates two robots and utilizes several conveyors to streamline the packaging workflow.

This system has yielded a 20% increase in production, escalating the output from 400 to 500 boxes per minute. NECCO's corporate industrial engineering manager, Frank Russo, notes that the system operates two 10-hour shifts per day during peak periods.

The collaborative effort involving our friends at JLS Automation resulted in the development of a system that transports 334-inch boxes of conversation hearts from existing upstream equipment through a picking cell. After filling the boxes with the candy hearts, they progress through a series of conveyors, where scanning and robot-assisted stacking take place.

The high-speed nature of the candy box approach presented a challenge for the application. To address this, JLS Automation's president, Craig Souser, explains the need for accumulation and metering using conveyors to regulate the flow and present the boxes to the robots in the required groupings.

Inside the picking cell, the robots create patterns of four, six, eight, or 12 boxes based on the information gathered through scanning. The boxes are then moved through a shrink wrapper or form/fill/seal machine, loaded into cases manually, and prepared for shipment.

During peak production, the system achieves a packaging rate of two cases per minute, a commendable pace given the quantity of boxes per case. Russo expresses satisfaction with the system's performance, emphasizing its efficiency during peak production periods.

If you're keen on revolutionizing your production processes, embracing cutting-edge solutions, and staying ahead in the confectionery industry, now is the time to initiate conversations. Connect with industry experts, explore automation possibilities, and embark on a journey towards increased productivity and customer satisfaction.

Let's sweeten the future together – reach out to us at 1-888-600-3080 or on our contact page, collaborate, and discover the endless possibilities that await in the world of confectionery manufacturing. Your next breakthrough could be just a conversation away.

Source: Packaging Digest

Recent Posts

-

Introducing the Turck Q130 HF Read/Write Head: Revolutionizing RFID Data Management

In today's fast-paced industrial landscape, efficiency and accuracy are paramount. The ability to se …Apr 30th 2024 -

Using Scan Tunnels to Track, Sort and Route Warehouse Packages

If you’re using conveyor lines to move products, packages and shipments through your warehouse, the …Apr 17th 2024 -

Embracing Collaboration: How Universal Robots Transformed DeAngelo Marine Exhaust

When the welding robots made their debut at DeAngelo Marine Exhaust, there was a mix of excitem …Apr 11th 2024