Feb 2nd 2023

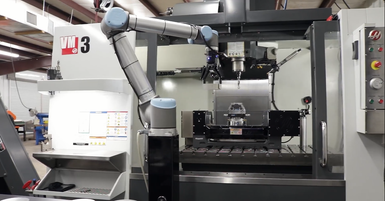

Reduce Cobot Setup Time by Up to 90%

Robot installation and integration into production processes still take a lot of labor, notwithstanding how simple robot setup and programming have grown over the past ten years. Many manufacturers, e

…