World's Third Largest Motorcycle Manufacturer Uses Universal Robots

Improving productivity and ergonomics is a large part of what drove Bajaj Auto Ltd. to choose Universal Robots’ cobots to automate their assembly lines and become the first company in India to implement a collaborative robots solution. Due to the growing number of motorcycle models being produced, Bajaj needed an automation solution that could be deployed horizontally. The benefits of Universal Robots cobots were primarily an improvement in productivity, flexibility and reliability as well as a low payback period and extra safety compared to other solutions.

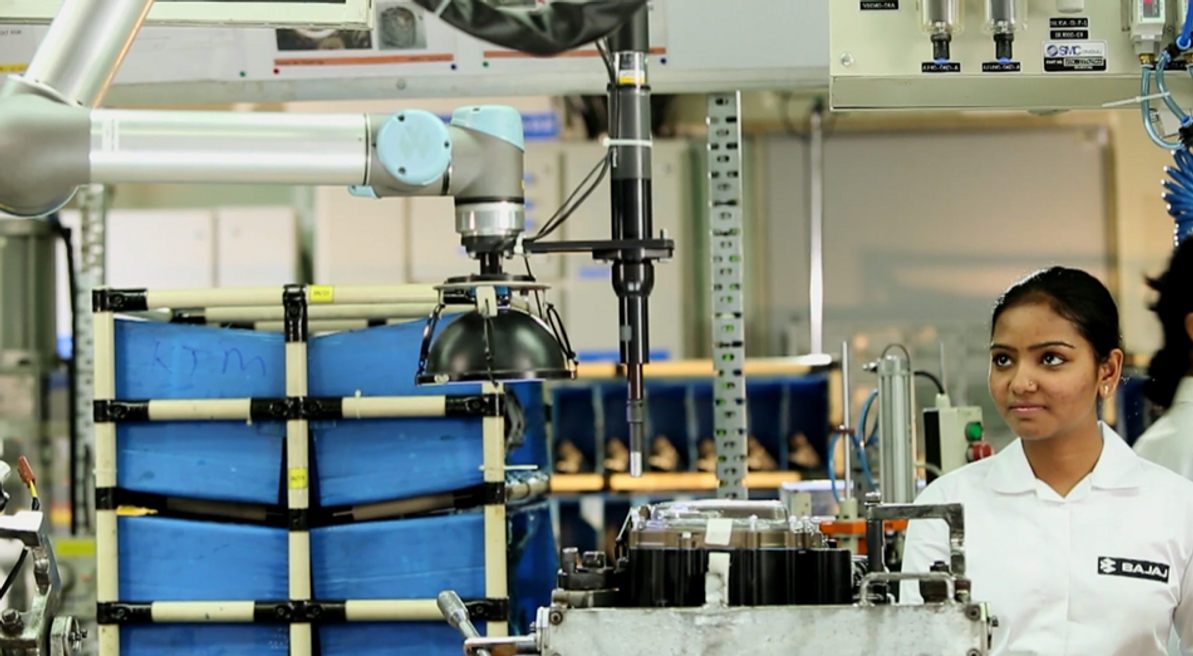

“Two-wheeler assembly lines are highly labor-intensive, spatially challenged and they have physically taxing movements that require high-end precision,” says Vikas Sawhney, General Manager Engineering (Robotics and Automation) Bajaj Auto. He also notes that almost half of assembly line employees at the facility are women, who report positive reviews of the cobots. Rameshwari Uffels, an assembly line operator had this to say, "Operating this advanced technology is very interesting and easy. Me and the other employees enjoy working with these cobots.”

Bajaj spent three months testing Universal Robots for applications such as material handling and machine tending, tasks which are shared with employees. Thanks to the collaborative robots, the company can now carry out repetitive tasks with reliable precision.

Are you ready to test out a Universal Robots collaborative robot application at your manufacturing facility? Contact us for more information or attend one of our informal, free collaborative robot demonstration days. Register here.

Recent Posts

-

Introducing the Turck Q130 HF Read/Write Head: Revolutionizing RFID Data Management

In today's fast-paced industrial landscape, efficiency and accuracy are paramount. The ability to se …Apr 30th 2024 -

Using Scan Tunnels to Track, Sort and Route Warehouse Packages

If you’re using conveyor lines to move products, packages and shipments through your warehouse, the …Apr 17th 2024 -

Embracing Collaboration: How Universal Robots Transformed DeAngelo Marine Exhaust

When the welding robots made their debut at DeAngelo Marine Exhaust, there was a mix of excitem …Apr 11th 2024