Jun 14th 2023

Understanding Chiller Surge: Causes, Prevention and the Advantage of SMC Chillers

Chiller surges can have detrimental effects on the performance and efficiency of refrigeration systems. In this article, we will delve into the causes and prevention of chiller surges and highlight the advantage of SMC Chillers as a reliable solution. By understanding chiller surge dynamics and implementing effective preventive measures, you can ensure optimal chiller operation and longevity.

What is Chiller Surge?

Chiller surge occurs when there is a disruption in the flow of refrigerant through the compressor, leading to pressure fluctuations and instability. This can result in reduced cooling capacity, increased energy consumption, and potential damage to the chiller components. It's important to differentiate between stall and surge on a chiller. Stall refers to a temporary reduction in flow, while surge refers to a complete disruption and reversal of flow.

Understanding the Causes of Chiller Surge

Several factors can contribute to chiller surges. These include:

- Inadequate flow control: Improper design or sizing of control valves and throttling devices can lead to flow instabilities, causing surges.

- Insufficient refrigerant charge: An incorrect amount of refrigerant can affect the flow dynamics and trigger surges.

- System imbalance: Mismatched components, such as compressors and expansion valves, can cause pressure imbalances and result in surges.

- Variable load conditions: Rapid changes in cooling demand or load fluctuations can lead to surges if the chiller system is not properly equipped to handle these variations.

Recognizing the Signs and Symptoms of Chiller Surge

Detecting chiller surge is crucial for timely intervention. Common signs of chiller surge include:

- Abnormal noise: Unusual sounds such as banging or hissing coming from the chiller indicate potential surge issues.

- Vibrations: Excessive vibrations during operation may indicate a surge condition.

- Reduced cooling capacity: If the chiller is unable to meet the required cooling demand, it may be experiencing surge-related problems.

- Unstable pressure readings: Fluctuating or erratic pressure readings can be indicative of chiller surge.

Preventing Chiller Surge

To prevent chiller surges, it is essential to implement the following measures:

- Proper flow control: Ensure the chiller system is equipped with well-designed control valves and throttling devices to maintain stable flow.

- Optimal refrigerant charge: Regularly check and maintain the correct refrigerant charge levels to promote efficient flow.

- Balanced system design: Ensure that chiller components are matched and sized appropriately to minimize pressure imbalances.

- Load management: Implement strategies to manage load variations effectively, such as utilizing multiple compressors or employing variable speed drives.

Introducing SMC Chillers

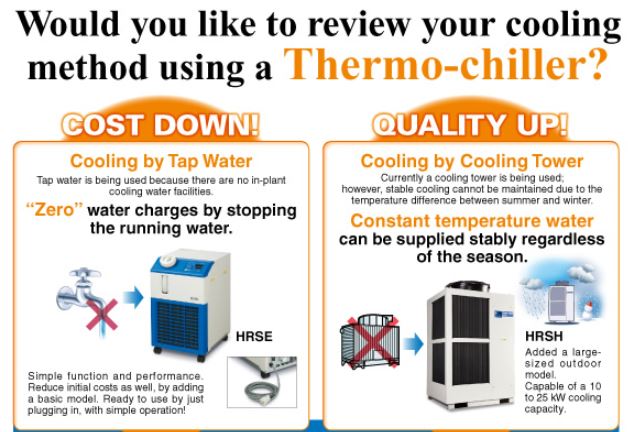

As a distributor, we proudly offer SMC Chillers as a reliable solution for chiller surge prevention. SMC Chillers are renowned for their advanced technologies and superior performance. They incorporate innovative anti-surge control mechanisms, ensuring stable and efficient operation even under varying load conditions. With a wide range of models and customizable options, SMC Chillers provide tailored solutions for diverse industrial applications.

Chillers are created to meet particular operating requirements and system requirements. With correct maintenance and operation in accordance with design intent, a well-chosen chiller will not spike. Changes in operating conditions can lead to surges, especially when the load is minimal. A surge could be brought on by maintenance issues including blocked tubes, low refrigerant charge, or non-condensables in the refrigerant. It can also be brought on by improper control of water flow rates and condenser water temperatures. Low load (surge) challenges can be avoided or resolved with hot gas bypass or VFDs.

Chiller Evaluation Program - Try Before You Buy

Take one of our chillers for a test drive before committing.

Program Features

- Validate your cooling process

- Evaluate our chiller before purchase

- Variety of styles and capacities

- Over 70 chillers available

- Evaluation period up to 45 days

SMC Chiller Advantages

- High quality

- Precision control

- Energy savings

- Global support

Chiller surges can have detrimental effects on chiller performance, energy consumption, and equipment lifespan. By understanding the causes and implementing preventive measures, you can mitigate the risks associated with chiller surges. Shop online now or contact us today to learn more.