Warehouse Automation: Fill More Orders with Less Labor

The rapid expansion of distribution and fulfillment centers, fueled partly by an increase in eCommerce, has put warehouse automation in the limelight. The focus was sharpened even more in 2020, as COVID-19/work-from-home trends increased e-commerce growth.

Warehouse automation will become increasingly vital in order to keep up with rising demand levels, as it contributes to greater productivity, efficiency, order accuracy, and safety. Furthermore, higher automation levels enable warehouses to respond to new social distancing techniques and labor shortages by employing fewer people. This trend is unlikely to be slowed by the reemergence of the "experience economy." Micro-fulfillment systems are becoming increasingly popular as consumers demand shorter delivery times.

Operations could explore automating the picking (and restocking) process to boost productivity and fulfill peak demand. Accelerating fulfillment gives your company a competitive advantage by allowing it to meet service level agreements (SLAs) like same-day or next-day delivery.

The retail eCommerce boom, which is moving away from brick-and-mortar shopping, is one of the key growth factors in the warehouse automation market. A dramatic growth in online purchasing, particularly in the grocery industry, is occurring as a result of increased mobile use, internet access, and post-pandemic lockdowns.

Modern fulfillment and shipping techniques are required as a result of these paradigm developments. With 66 percent of customers choosing e-vendors based on delivery options, 63 percent citing delivery speed as a critical criterion and 77 percent prepared to pay more for faster delivery, quick order fulfillment is no longer a luxury. With Amazon driving the way for speedier shipping, warehouses are left to meet these expectations alone.

Investing in warehouse automation has become crucial for gaining and retaining consumers as vendors confront this challenge. More money is being invested in automated systems that can handle small to big individual orders rather than bulk transportation models, which is shaping the warehouses of the future.

When labor is scarce, make your existing workforce more efficient by providing them with tools that will improve their job performance. Implementing barcode scanning to confirm picks, for example, will improve order accuracy. Furthermore, autonomous mobile robots can aid in the recruitment, training, and retention of staff. By sending an associate straight to a pick site, the danger of human error is decreased, and productivity rises, resulting in more orders being shipped.

Only about 40% of the warehouse business employs automation, and of that, only about 30% to 35% use basic automation such as package conveyance. Despite all of the hype, it appears that a few early "first movers," such as Amazon, FedEx, Target, and Walmart, continue to dominate the market.

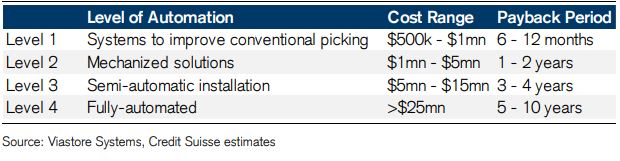

The cost of warehouse automation varies depending on the level of automation used at a given location. Systems that improve traditional picking, for example, cost $500k to $1 million, whereas a fully automated solution set costs $25 million or more. Payback on automation expenditures can range from 6 to 12 months for simple projects to 5 to 10 years for a fully automated warehouse.

Warehouse automation will become increasingly crucial in order for businesses to keep up with demand and remain competitive. Organizations with more advanced warehousing operations may be rewarded with a bigger multiple in the future. Working with available warehouse automation tools helps you to create a flexible and scalable picking strategy when you need it. Increase efficiencies throughout your whole warehouse, starting with your labor staff, by contacting one of our automation specialists today for an assessment before peak season bottlenecks.

Sources: Credit Suisse, 6 River Systems, SelectHub

Recent Posts

-

Using Scan Tunnels to Track, Sort and Route Warehouse Packages

If you’re using conveyor lines to move products, packages and shipments through your warehouse, the …Apr 17th 2024 -

Embracing Collaboration: How Universal Robots Transformed DeAngelo Marine Exhaust

When the welding robots made their debut at DeAngelo Marine Exhaust, there was a mix of excitem …Apr 11th 2024 -

How to Speed Up Your Warehouse Packing by 33% with Machine Vision

Packing benches are some of the busiest areas of most warehouses, with thousands of items to pack i …Apr 4th 2024