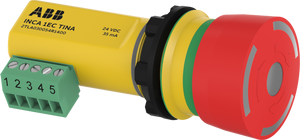

ABB Smile 11 EAR Tina Emergency Stop, M12 5‑Pin, LED, Reversed Button Mount, 24 VDC, 2TLA030050R0100

ABBCompact ABB Smile 11 EAR Tina emergency stop station with yellow enclosure, Tina/DYNlink interface, M12 5‑pin male connector, and LED status indication; up to PL e / Cat. 4 for demanding industrial safety applications.

The ABB Smile 11 EAR Tina is a compact emergency stop station in a robust Smile enclosure, designed for distributed machine safety on modern production lines. It integrates ABB’s Tina adaptation for DYNlink dynamic safety circuits, making it a plug‑and‑play solution with Vital safety modules and Pluto safety PLCs while minimizing wiring and enabling advanced diagnostics. A high‑visibility mushroom head with integrated status LED gives operators clear indication of circuit status directly on the device, reducing troubleshooting time and improving overall safety.

This unit features a single M12 5‑pin male connector and a reversed button attachment (from the bottom), which simplifies mounting on machine frames, aluminum extrusions, conveyors and guarding. Rated up to performance level e / category 4 according to EN ISO 13849‑1 when used in an appropriate safety architecture, it is suitable for applications that demand the highest functional safety integrity. With IP65 protection, a plastic housing and a slim footprint, Smile 11 EAR Tina is an excellent choice for OEMs and maintenance teams standardizing on ABB Jokab Safety components across their installations.

Key features

-

Emergency stop in compact Smile enclosure for machine fronts, guards, and conveyor systems.

-

Tina adaptation unit included for DYNlink dynamic safety circuits (Vital/Pluto compatible).

-

Status LED in the button (green/red) for clear visual indication of safety circuit status.

-

1 x M12 5‑pin male connector for quick plug‑in installation and daisy‑chaining in series.

-

Reversed button attachment from the bottom to ease mounting on profiles and panels.

-

Rated up to PL e, Cat. 4 per EN ISO 13849‑1 depending on system design.

-

IP65 protection class, plastic housing, robust design for industrial environments.

-

Supports info signal from each emergency stop for enhanced diagnostics and maintenance.

Technical specifications

-

Manufacturer: ABB Jokab Safety

-

Series: Smile Tina

-

Model: Smile 11 EAR Tina

-

Part number: 2TLA030050R0100

-

Function: Emergency stop device in enclosure with LED indication

-

Electrical:

-

Supply voltage: 24 VDC (17–27 VDC operating range, typical for Smile Tina)

-

Current consumption: approx. 47 mA (about 57 mA with max info output load)

-

Info output current: up to 10 mA

-

-

Connections:

-

1 x M12 5‑pin male connector (dynamic safety / Tina interface)

-

-

Performance and safety:

-

Performance level: up to PL e

-

Safety category: up to Category 4 (EN ISO 13849‑1) depending on system architecture

-

Suitable for SIL 3 architectures according to EN 62061 / IEC 61508 when correctly applied

-

-

Mechanical and environmental:

-

Actuating force: approx. 22 ± 4 N

-

Actuator travel: approx. 4 mm to latch

-

Protection: IP65

-

Housing material: Plastic enclosure (Smile housing, yellow front)

-

Mechanical life: > 50,000 operations

-

-

Dimensions and weight (unit):

-

Width: 0.040 m (40 mm)

-

Height: 0.097 m (97 mm)

-

Depth: 0.057 m (57 mm)

-

Net weight: 0.076–0.159 kg (range from ABB and distributor listings)

-

-

Standards and conformity:

-

EN ISO 12100:2010

-

EN ISO 13849‑1

-

EN 62061

-

CE declaration available (2TLC172016D0201)

-

Recommended applications

-

Distributed emergency stops along conveyor lines and material handling systems.

-

Line safety on packaging, assembly, and machining cells using Vital or Pluto‑based safety networks.

-

Guard and enclosure E‑stops on aluminum extrusion frames, fencing, and access doors.

-

Retrofit safety upgrades where fast M12 plug‑in wiring and diagnostic capability are required.

Highlights

-

High safety level (up to PL e / Cat. 4) in a small footprint, helping meet machine safety standards without bulky hardware.

-

Reduced wiring and installation time thanks to the Tina/DYNlink interface and M12 connector, especially when multiple E‑stops are connected in series.

-

Faster troubleshooting with integrated LED status and info signal from each device, supporting higher uptime on critical production assets.