Jun 1st 2022

Machine Wiring Concepts

Electrical wiring systems are mostly standardized, with a number of rules, regulations, and laws governing them. According to electrical laws and standards, electrical wiring must be done appropriately and safely. If electrical cabling is done poorly or without according to any standards, it can result in short circuits, electric shocks, device damage or malfunction, all of which reduce gadget life.

Before the actual installation work for industrial wiring can begin, several variables must be considered. These considerations include the type of building, ceiling, wall, and floor construction, wiring procedures, and installation requirements, among others.

Electrical Protection

Before beginning any installation work, the first and most important consideration is the personnel's safety. Electricity is harmful, and coming into direct or indirect touch with it while the power is turned on can result in serious injury or even death. To keep your workplace safe, follow the actions listed below.

- Avoid any direct contact with live or energized circuits by using safety equipment such as goggles, gloves, and shoes.

- Have the ability to identify the exposed live elements of electrical equipment using skills and techniques.

- While installing or connecting wires, turn off the power source.

- The main switchboard, which should have circuit breakers, must manage the electricity delivered to the installation.

- Conductive tools and materials must be maintained away from live circuit or equipment components.

- Non-conductive hand tools that are rated for electrical work should be used. If they are utilized for voltage (or current) ratings other than those specified, the tool's insulation strength will deteriorate, resulting in electric shock.

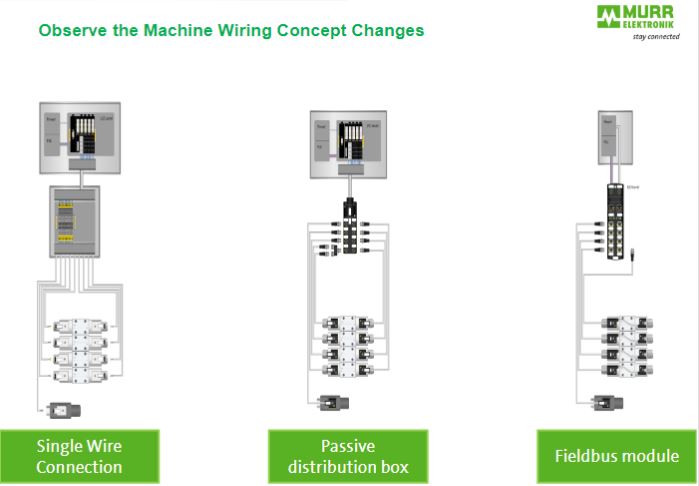

There are several types of wiring concepts to consider before embarking upon any new project. Below is a breakdown of options with pros and cons of each option.

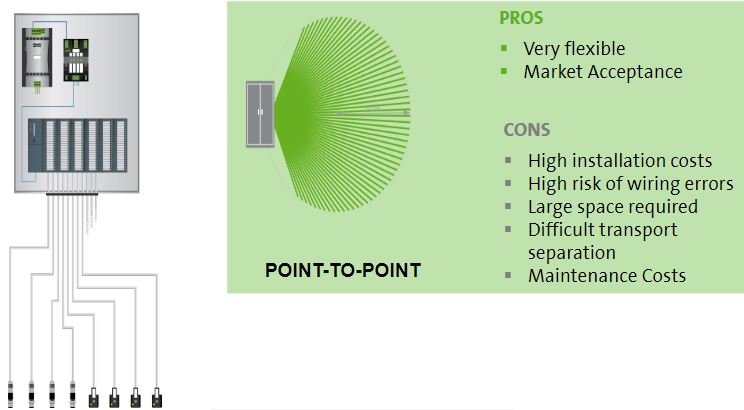

Point to Point

The term "point-to-point wiring" refers to a method of assembly in which the components are installed on tube sockets and/or terminal strips, and the connections between them are then hand-wired to complete the circuit.

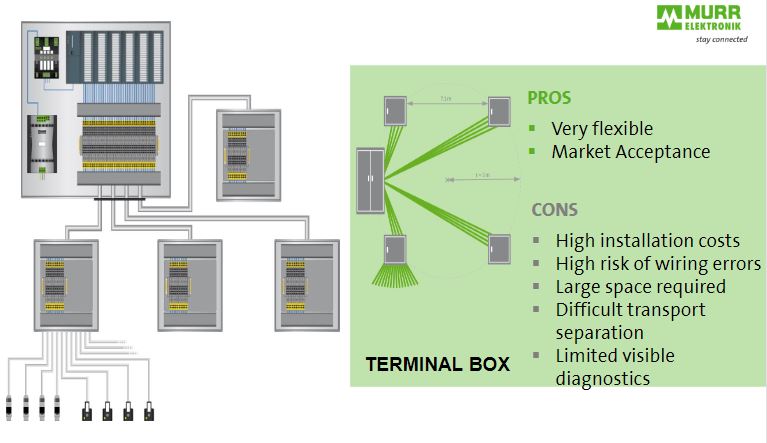

Terminal Box

A terminal block (also known as a connection terminal or a terminal connector) is a modular block with an insulated frame for connecting two or more wires. It is made up of two parts: a clamping component and a conductor strip. The graphic below depicts a typical simplest terminal block.

A current carrying element is housed in the insulating body of a terminal block (a metal strip or terminal bar). It also serves as a foundation for the clamping element. The block's body is designed with a mounting mechanism that allows it to be easily put on or removed from a PCB or mounting rail. The majority of terminal blocks are modular and DIN rail mounted. This enables us to scale up the number of terminals in response to demand. Connections are more secure and wires are better organized using terminal blocks.

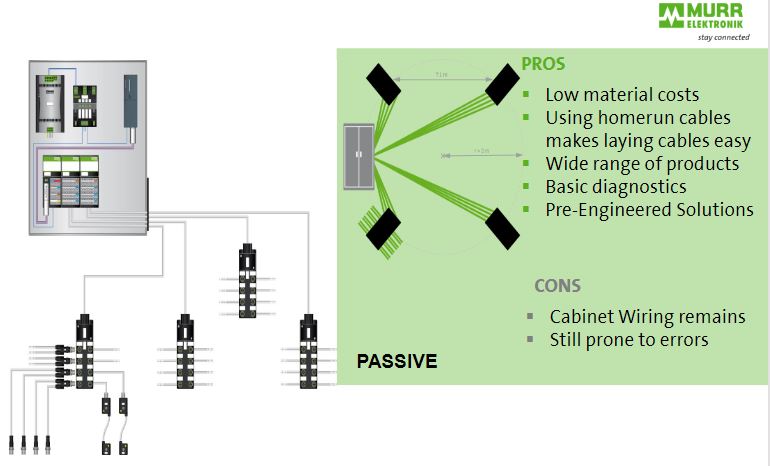

Passive

A passive element is an electrical component that dissipates, stores, and/or releases energy rather than generating it. Resistances, capacitors, and coils are examples of passive elements (also called inductors). In circuit diagrams, these components are called Rs, Cs, and Ls, respectively. They are connected to active elements in most circuits, which are often semiconductor devices like amplifiers and digital logic processors.

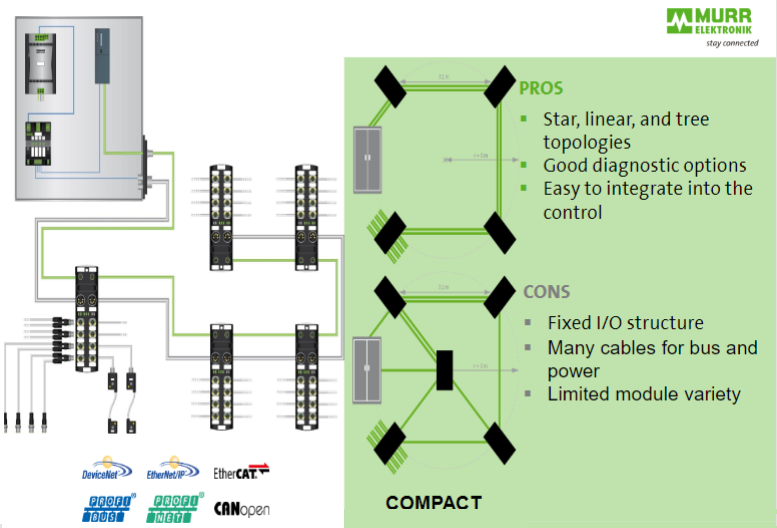

Compact

Compact wiring systems include star, linear and tree connections. In a star connection, one end of each of the three wires is linked to a common point in the shape of a Y, forming the three phases and the common point the neutral. A linear circuit is an electric circuit with constant circuit parameters (resistance, inductance, capacitance, waveform, frequency, and so on). In other terms, a linear circuit is one whose parameters do not vary with regard to current and voltage. A tree system is another way to distribute electrical energy in a building. The wiring arrangement of this system resembles a tree since lesser branches are pulled from the main branch.

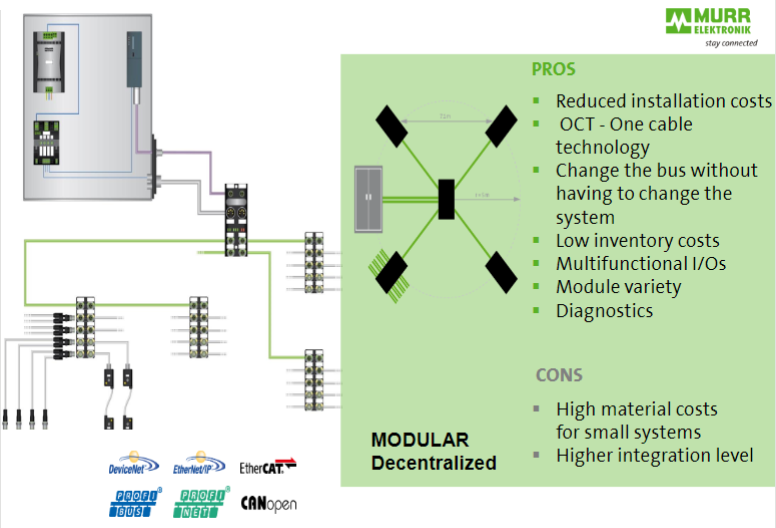

Modular

Modular wiring is a prefabricated wiring system that connects the distribution board to the farthest point on each circuit by simply plugging it in.

Murrelektronik provides a diverse selection of electrical and electronic installation products. All of our products are made to function together and within your existing system. Whether you're looking to reduce installation and/or operating expenses or simply put together a more efficient machine, our comprehensive product range allows you to construct a system that suits your installation demands. Shop Murrelektronik products on our website here.

Sources: electronicshub.org/electrical-systems-and-methods-of-electrical-wiring; https://www.electricaleasy.com/2018/03/terminal-bl...; https://www.renesas.com/us/en/support/engineer-sch...; https://www.electronicshub.org/comparison-star-del...; https://www.electricaltechnology.org/2013/12/the-m...; https://old.amu.ac.in/emp/studym/100013244.pdf; https://coresolutions.ie/systems/modular-wiring/#:...