Aug 4th 2022

Blog

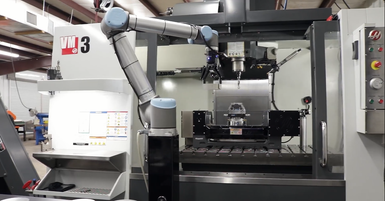

One of the most popular applications for collaborative robots on the market today is machine tending. As long as the robot is constantly receiving raw materials, a robotic machine-tending operati

…

Jul 14th 2022

Flexible Automation: Short-Term Relief or Long-Term Solution

At Automate 2022, robots were performing various pick-and-place jobs, playing chess, welding, painting, and other activities. Despite the fact that the robots were programmed to do one thing for

…

Apr 13th 2022

So Easy a Three Year Old Can Do It! Universal Robots: Come for the Safety, Stay for the Ease of Use

In the past 20 years, properly programming an industrial robotic or motion control solution required a well-trained person. During this time, robot and motion control vendors would pop up to brag abou

…

Mar 1st 2022

World's Third Largest Motorcycle Manufacturer Uses Universal Robots

Improving productivity and ergonomics is a large part of what drove Bajaj Auto Ltd. to choose Universal Robots’ cobots to automate their assembly lines and become the first company in I

…

Jul 21st 2021

How to Choose Between Cobots and Industrial Robots

When choosing between a collaborative robot and a traditional industrial robot, one must consider all aspects of the application. No one solution is better for all applications.Advantages and Disadvan

…

Jun 8th 2021

How To Prevent 24% of Workplace Injuries

In the United States, overexertion and repetitive motion account for 24% and 8% of workplace injuries, according to Universal Robots, the company that produces collaborative robots designed to as

…