Jun 6th 2024

Understanding Industrial Chillers: Benefits, Types, and Solutions

What is a chiller?

Industrial chillers utilize refrigeration technology to remove heat from equipment, process fluids, and manufacturing areas to maintain appropriate temperatures for the environments and applications in which they are deployed. They are commonly used in sectors involving injection molding, machine tooling, paper processing, metal plating, food and beverage, pharmaceuticals, research labs and other industrial categories that call for precise operating temperatures. Chillers offer efficient thermo control to remove excess heat.

What do chillers do and what are the biggest benefits of an industrial chiller?

A water chiller prevents equipment from overheating, which can extend its lifespan and reduce production downtime. In some ways, it could be considered part of predictive maintenance. It may also be used to cool process fluids like various chemicals and oils, which can reach dangerously high temperatures in manufacturing environments and possibly cause fires. A water chiller will help protect workers, equipment and property by maintaining appropriate ambient temperature for the application. Removing the variables related to temperature makes process development and optimization easier while maintaining the highest possible quality.

What kinds of chillers are available?

There are several kinds of chillers available, and two of the most commonly used are water-cooled and air-cooled chillers. In a water-cooled chiller, chilled water runs through a piping system that absorbs heat from the air. An air-cooled chiller uses fans and refrigerant to transfer heat from a process to the outside.

SMC Corporation’s HRS, HRS-R, HRSE compact recirculating chillers are designed for a wide range of single-point applications in both industrial and technology settings. Each unit’s design is powerful enough for the factory, while also being ergonomic and compact for lab installations. Coolant can be either heated or cooled within the set temperature range. Available with a choice of eight cooling capacities, air or water cooled refrigerant, global power supply options, and US stock availability, SMC chillers are a reliable and accessible choice for thermo cooling.

The SMC HRS Series is a floor-mounted series of temperature control equipment. A coolant circuit runs between the chiller and the heat source, drawing off the heat. That heat is then removed from the coolant by a refrigeration circuit. Heat can be generated by industrial processes or machinery running. The HRR Series operates in a similar manner but is packaged to mount on a standard 19-inch rack, which frees up floor or tabletop space and can also allow for stacking and mobility.

The HRS and HRR Series are well known for reliable service, tight temperature control, compact design, easy operability, strong status reporting, and a wide range of capacities. While not completely unique in the marketplace, the HRR rack mount style is very uncommon. SMC’s 6 capacities and water or air cooling options are one of the best offerings in the market.

Chiller Evaluation Program

SMC has a trial program that allows customers to evaluate chillers for up to 30 days. Chillers can be a significant investment and the trial program allows you to test the product with your application before committing to a purchase.

Program Features

- Validate your cooling process

- Evaluate our chiller before purchase

- Variety of styles and capacities

- Over 70 chillers available

- Evaluation period up to 30 days

SMC Recirculating Chillers Guide

Success Stories

Goal: Switch from City Water-sourced Cooling Systems

Many end-users of the OEM’s gable-top packaging machines wanted the option to change from city water-sourced cooling systems. An SMC Trial Chiller was introduced. The OEM’s end-users operate the gable-top carton packers in ambient temperatures - from high (adjacent to milk pasteurizers) to chill (juice fillers), so the engineers had to simulate many scenarios for cooling capacity.

The cartons start as flats then folded into rectangles, next the bottoms are heat sealed, then chilled to set the seal. The chiller must perform in various ambient temp. filling facilities to cool the cooling plate to set the carton seal in < 1 sec.

The engineers embraced the evaluation program and tested a HRS030-R in their labs to simulate many conditions their end-users would operate their fillers.

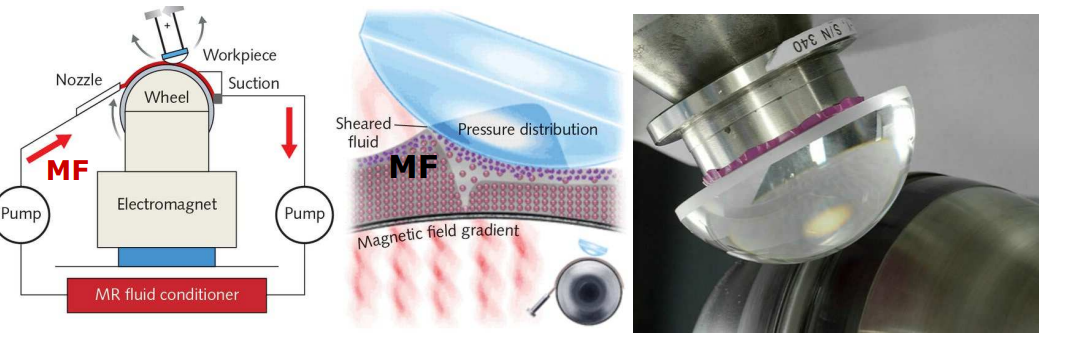

Goal: Keep an Optical Polishing Machine from Overheating and Halting Production

The electromagnetic wheel overheating will shut down the lens polisher and affect the MF fluid’s viscosity; Lytron’s chiller was underperforming. Zach and Doug called John to help size the evaluation chiller (HRS050); the OEM installed it on their contract manufacturing side of the company with great results during the evaluation period. The contract manufacturing side purchased the HRS050 and replaced all their old units.

Goal: Source a Higher Cooling Capacity Rack Mount Chiller

The OEM builds a variety of ultrasonic welders and requires the higher cooling capacity available with HRR. The OEM leveraged the Chiller Evaluation Program to sample a properly sized HRR for testing. After months of in-house operation, the OEM was satisfied and ordered two units. The HRR for the first ultrasonic welder performed to specification but the second HRR for another welding unit kept indicating an “alarm 21” fault causing an emergency shut down on the welder. After initial inspection, it was believed the cause was a faulty solder joint on the control board, but some chiller engineers were skeptical this was the problem. Because the OEM had to ship in four days or else pay penalties to the end-user, this problem needed to be solved ASAP.

SMC staff diagnosed the root cause as the control display board not the solder joint and after quick replacement, the repaired HRR was approved for reshipping. The OEM was highly impressed with the level of service and has been acquired by Emerson, parent of ACSO/Numatics, and their engineers prefer to collaborate and specify SMC components over their new ‘in-house’ brands.

Take control of your cooling needs and ensure your equipment operates at peak performance with SMC’s advanced chiller solutions. Whether you're looking to prevent overheating, extend equipment lifespan, or optimize your processes, our HRS and HRR Series chillers deliver unmatched reliability and efficiency. Don't miss out on the opportunity to experience the benefits firsthand. Join our trial program today and evaluate the perfect chiller for your application, risk-free for up to 30 days. Contact us at 1-888-600-3080 to learn more and schedule your trial. Transform your temperature control with SMC – where precision meets reliability.

Find out what the most reliable, top rated chillers and thermal management solutions are here.