Zebra Robotics Fetch100 Shelf AMR

Zebra Robotics Automation

Automation Distribution helps you design, build, and support high-performance automation cells with SMC, Universal Robots, WAGO, Turck, PULS, Zebra, Yaskawa and more.

Collaborative Operation

Automate existing manual cart operations with Fetch100 Connect. Workers load, unload, and position carts, while our AMRs handle pickup and delivery once the carts are ready.

Enhance Operational Workflows

Tackle diverse warehouse challenges head-on by automating putaway processes, accelerating the dock-to-stock cycle, and increasing daily throughput with seamless transportation of goods from storage systems to packout.

Maximize Productivity

Replenish production lines faster to avoid downtime. Let our AMRs transport raw materials, work pieces or kitted components for ongoing material delivery to lineside operations.

Case Studies

Austin Lighthouse Empowers Employees, Doubles Productivity

Austin Lighthouse is a non-profit organization that offers education and training to people who are visually impaired. Through its warehouse and distribution space, the organization provides logistical support to the federal government and offers commercial warehousing services. Read more.

Waytek Improves Throughput by 25% with Autonomous Mobile Robots

Waytek, a leading automotive electrical component distributor, struggled to keep up with the ever-increasing demand for their products amidst a worker shortage. With order volumes approaching 800 per day and a conveyor system unable to keep pace with the volume, they needed a way to scale output within the same 100,000-square-foot facility. Read more.

With the Fetch100 Connect system, automating cart-based material handling processes is now quicker and simpler. Intelligent mobile robots can carry out autonomous cart transportation, eliminating the need for labor-intensive walking and travel time, in place of manually transferring carts from one place to another.

Key Benefits

Warehouse Carts 2.0

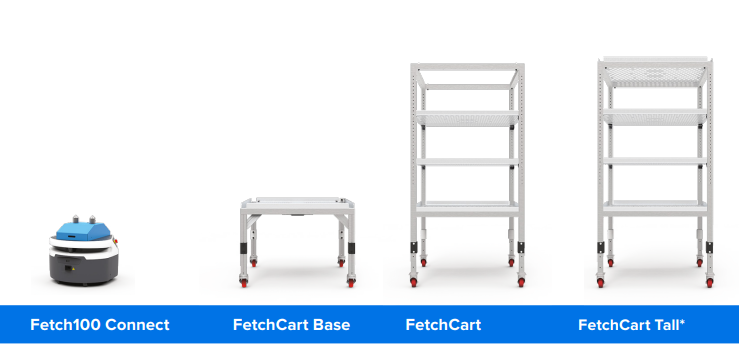

The Fetch100 Connect AMR system features an advanced mobile robot that can autonomously pick up and drop off FetchCarts to any location within your facility. FetchCarts are available in three sizes—Standard, Tall and a flexible cart Base option that allows you to customize the cart to suit your specific payload. Shelf dimensions available in the brochure.

FetchCart Base serves as the starting point for designing your own customized material transport system and applying automation creatively and efficiently throughout your facility. You can accommodate a wide variety of payloads and maximize capacity per your application requirements. FetchCart Base uses the same reliable docking mechanism as our standard FetchCarts, so Fetch100 Connect AMRs interface seamlessly. Some unique applications include: detrash and dunnage removal, parts and tools delivery, replenishment of packing materials, gravity feed racks for manufacturing work cells, and many more.