Aug 28th 2025

Photoneo 3D Vision Transforms Brake Disc Production at Italian Foundry

Modern manufacturing demands automation solutions that are both intelligent and robust. A perfect example comes from Fonderia di Torbole, a leading Italian foundry specializing in automotive parts, where Tiesse Robot partnered with Photoneo to deliver a cutting-edge automation system. The project showcases how 3D vision technology can power high-speed bin picking of heavy, complex parts.

The Challenge: Automating the Unpredictable

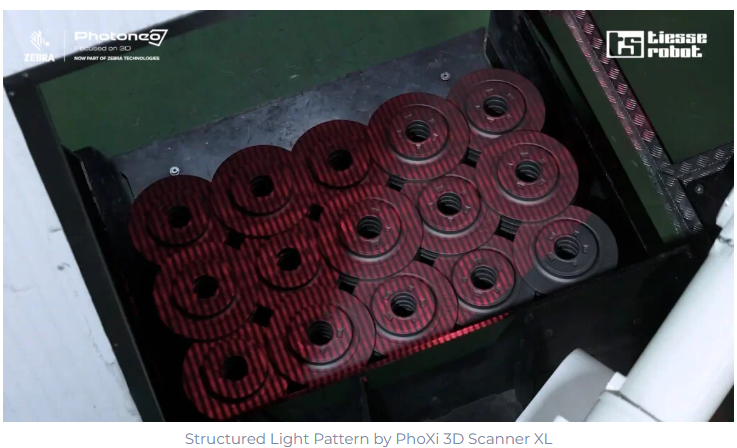

At the start of the line, raw brake discs weighing up to 15 kg are heaped in large bins. Automating this process required overcoming several hurdles:

-

Identifying discs in random orientations within a semi-structured bin

-

Handling reflective and dark metal surfaces

-

Calculating safe, collision-free paths for robot arms and grippers

-

Achieving a rapid cycle time under 45 seconds

Without advanced vision, these conditions would make automation nearly impossible.

The Solution: Photoneo-Powered Bin Picking

Tiesse Robot designed a fully automated solution centered around Photoneo’s PhoXi 3D Scanner XL and Bin Picking Studio.

-

PhoXi 3D Scanner XL provides high-resolution scans of entire bins, capturing precise 3D data even in chaotic environments. Its large scanning volume and rugged design make it ideal for the harsh conditions of a foundry.

-

Bin Picking Studio serves as the system’s “brain,” identifying pickable discs, determining their orientation, and generating optimized, collision-free paths for the robots.

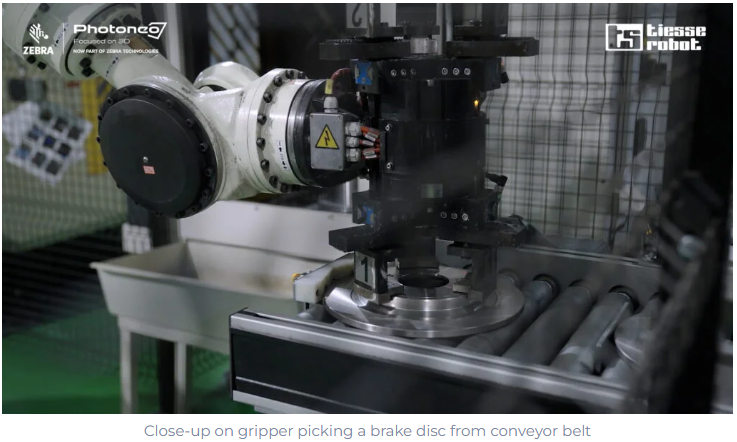

Armed with this intelligence, a Kawasaki RS080N robot equipped with a magnetic gripper picks, flips if necessary, and places each disc perfectly for the next stage of production.

A Three-Stage Automated Workflow

The solution integrates three robotic islands, ensuring seamless production from raw part to finished product:

-

Brake Disc Bin Picking – Vision-guided Kawasaki RS080N robot picks and orients raw discs.

-

Post-Turning Operations – A high-payload Kawasaki ZX165U robot loads/unloads drilling and balancing stations, assisted by 2D vision.

-

Final Inspection & Outfeed – Another ZX165U robot handles washing, dimensional inspection, laser marking, and prepares discs for painting.

This connected workflow ensures precision, consistency, and continuous material flow across the production line.

The Results: Efficiency and Reliability

By leveraging Photoneo’s 3D vision, the system delivered:

-

Unmatched Reliability – Accurate, repeatable picking of heavy brake discs in any orientation

-

High Throughput – Meeting the 45-second cycle time target to keep production running at peak capacity

-

Smart Automation – Seamless path planning and robot communication to ensure smooth, autonomous operation

-

Process Continuity – Establishing a foundation for a fully automated production cycle from bin to paint line

Why This Matters

This project proves that 3D vision and robotics are redefining what’s possible in heavy-industry automation. By removing manual labor from one of the most demanding and unpredictable tasks, manufacturers like Fonderia di Torbole can achieve higher throughput, safer workplaces, and greater process control.

Ready to see how Photoneo’s 3D vision can solve your automation challenges? Contact us today to learn more about the PhoXi 3D Scanner XL and Bin Picking Studio for your factory floor.