Apr 3rd 2025

The Ultimate Cable Solution for Food & Beverage Applications

When it comes to food and beverage manufacturing, hygiene and safety are non-negotiable. Every component used in processing environments, including cables, must meet strict regulatory standards to prevent contamination and ensure operational reliability. However, finding cables that meet both UL safety standards and FDA food contact regulations has traditionally been a challenge—until now.

Why Standard Industrial Cables Fall Short

Most industrial cables are built with flame retardants that help them pass UL (Underwriters Laboratories) safety testing, which is essential for compliance with NFPA 79 and the National Electric Code (NEC). However, these same flame retardants often do not meet FDA food safety requirements, making them unsuitable for areas where food contact is a concern.

Additionally, cables used in food processing facilities must withstand harsh washdown procedures, which involve frequent exposure to high-pressure water, steam, and industrial cleaning agents. Without proper protection, cable jackets can degrade, leading to failures that pose serious safety risks.

Meet the LUTZE SILFLEX® FBP Cable

LUTZE has solved this industry-wide dilemma with its SILFLEX® FBP cables, specifically designed for food and beverage processing applications. These cables offer a unique combination of:

✅ UL and FDA compliance, simplifying inspections and eliminating the need for special exemptions.

✅ Superior washdown resistance, ensuring durability against aggressive cleaning chemicals.

✅ Flexible, space-saving design, making installation and routing easier than ever.

✅ Food-safe materials, reducing the risk of contamination in sensitive environments.

✅ No conduit required in some areas, thanks to external wiring approval and food contact rating.

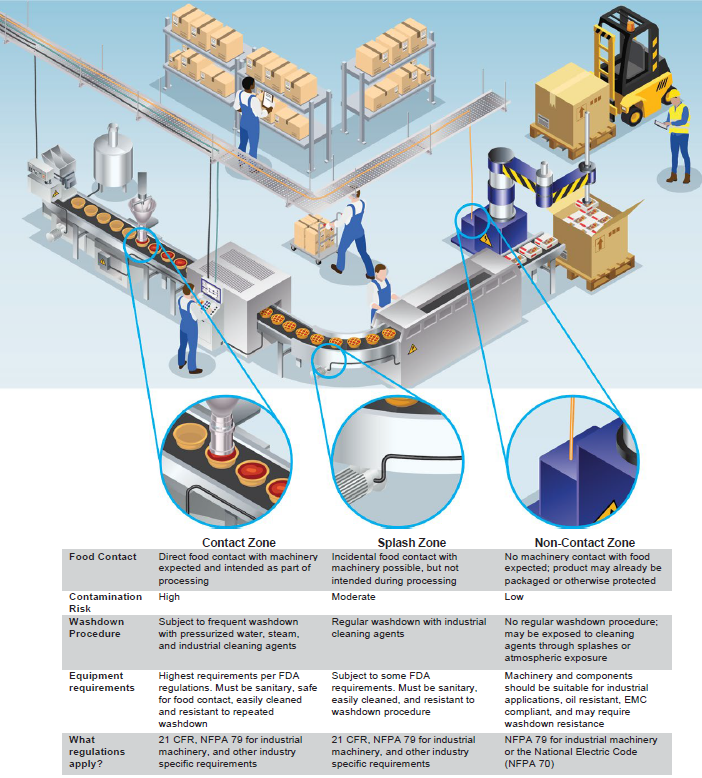

Built to Perform in Any Food Processing Zone

Not all areas in a food processing plant have the same contamination risk. LUTZE SILFLEX® FBP cables are designed to meet the specific requirements of different zones:

- Contact Zone: Direct food contact requires the highest level of sanitation, frequent washdowns, and FDA-approved materials.

- Splash Zone: Cables may come into contact with food indirectly and need to be resistant to regular cleaning procedures.

- Non-Contact Zone: Even where food exposure is minimal, equipment must meet industrial safety and durability standards.

The Smart Choice for Food & Beverage Manufacturers

With its patent-pending design, LUTZE SILFLEX® FBP is the ultimate cable solution for food and beverage processing environments. Whether you need control cables, shielded cables, or motor cables, LUTZE has a solution that meets the industry's highest safety and hygiene standards.

Looking for reliable, food-safe cabling?

Explore LUTZE SILFLEX® FBP cables and bring safety, compliance, and performance to your food and beverage operations.