Oct 31st 2024

Ensuring Safety in Challenging Environments with the World’s First Certified 3D Safety Radar

For manufacturing plant managers, safety is a top priority, especially in harsh industrial environments where traditional safety monitoring solutions can struggle to perform reliably. Enter the Leuze LBK system: the world’s first radar system certified for safety applications, specially designed for 3D monitoring of hazardous areas. With LBK, you're not only elevating safety standards but also embracing a revolutionary, robust solution capable of withstanding the toughest conditions in your facility.

Introducing the LBK 3D Safety Radar System: Your Safety Solution

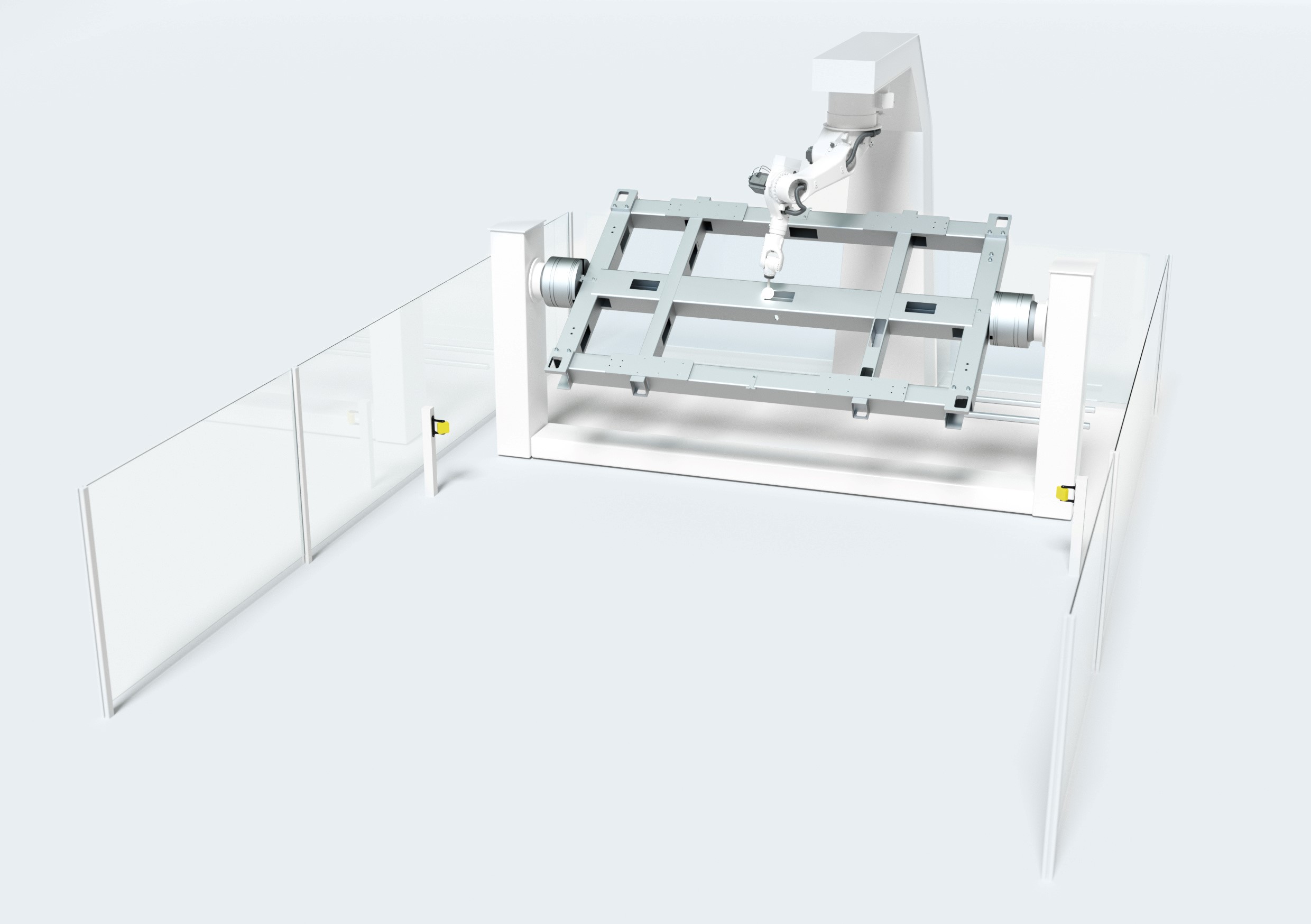

LBK is more than just a monitoring device; it’s a breakthrough technology. Engineered to detect human presence and body movements within designated hazardous zones, this system goes beyond simple area surveillance. It features a controller that can connect up to six sensors, creating a flexible, customizable safety net that adapts to your unique setup. This radar solution is tailor-made for industrial environments that push technology to its limits, ensuring your people and processes stay safe without compromising productivity.

Why LBK is the Safety Solution You Need

Let’s talk about the unparalleled advantages of the LBK system, which addresses common safety concerns in manufacturing settings:

- Reliable in Harsh Conditions: Dust, smoke, dirt, light, humidity—name it, and the LBK radar stands ready to operate effectively. It’s built to thrive in environments where other safety solutions may fall short, ensuring continuous protection no matter the conditions.

- Customizable to Fit Your Space: With LBK, you define the protected area’s boundaries by choosing the number and position of sensors and configuring the length and width of the monitored zone. This flexibility lets you adapt the system to the specific needs of your machinery and facility layout.

- No Shutdown from Static Objects: Unlike many traditional safety systems, the LBK radar allows static objects in the monitored zone without triggering a shutdown. This unique feature prevents unnecessary interruptions, so your processes can continue without a hitch.

- Seamless Integration: Fast integration is possible with LBK’s straightforward system design and a controller compatible with PROFIsafe or FSoE interfaces. This ensures you can get your safety system up and running without extensive setup times or technical headaches.

- Optional Expert Setup Service: Need help with configuration? Our certified experts offer a configuration and setup service to ensure the LBK system is perfectly optimized for your environment, taking the guesswork out of the process.

Where to Use the LBK 3D Safety Radar

The LBK system is a game-changer for guarding hazardous areas in challenging environments. For any machine’s hazardous working range, LBK ensures safe operation by protecting against unauthorized entry and the presence of personnel in high-risk zones. Plus, it maintains high availability, even in environments subject to contaminants like sawdust, welding sparks, or humidity.

Don’t Compromise on Safety—Elevate It with LBK!

The LBK 3D radar system represents a giant leap forward in industrial safety. Its ability to reliably monitor hazardous areas, even in the most challenging environments, means that you’re not just protecting your facility—you’re investing in a solution that adapts to your space, boosts productivity, and provides peace of mind. Contact our experts today at 1-888-600-3080 for a personal introduction to this revolutionary new system.