Aug 4th 2022

Advantages of CNC Automation

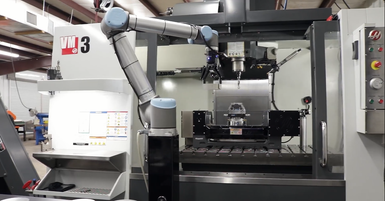

One of the most popular applications for collaborative robots on the market today is machine tending. As long as the robot is constantly receiving raw materials, a robotic machine-tending operation can be repeated indefinitely. Currently, humans handle the majority of machine-tending applications. CNC machines are widely used in modern machine shops (such as lathes and milling machines). These machines need to be maintained by employees, who feed the raw material (often referred to as the raw or blank part) into the machine and remove it when it has completed its task. To make up for the loss of personnel, however, as skilled workers become harder to find, businesses are integrating robots into their workshops.

Some businesses utilize robots to empty CNC or injection molding equipment within a single production phase. Robots allow you to minimize cycle time and continue the process continuously when production is operating nonstop by removing pieces from the machine's work area.

Cobots, or collaborative robots, are robots with limited force and capability. These are robots that do not require machine guarding or other safety measures and can be used. Without having to be walled off from their surroundings, cobots can be positioned next to another machine or human and programmed to carry out a certain activity.

Nevertheless, it is not as easy as it might seem to integrate a cobot with a CNC machine and program it to load and unload components. Selecting a robot that can complete the task and execute at a level that is on par with a human worker is necessary. Universal Robots collaborative robots, for example, are designed to mimic their human counterparts with similar joints, movement, reach and force sensitivities.

Produce More

Many different manufacturing processes can be carried out by a single CNC machine, all of which can be stored and managed by a single computer. These phases are organized in a sequence of logical development thanks to the autonomous operation and industrial automation aspects, which guarantees prompt process execution. As a result, it achieves the ideal balance of multivariate actions, prompt execution, round-the-clock operation, and faster processing. Therefore, even in the face of resource limitation, CNC machines may increase output and make it even more effective.

Quality Assurance and Repeatability

Computers that have been programmed to carry out a task consistently and without variation manage CNC machines. The repetitive use of the same set of steps during CNC machining results in accuracy that is within 1/1000th. Because of this, CNC machines provide improved accuracy and repeatability of work without sacrificing design consistency. Most significantly, CNC machines will continue to operate consistently even after repeated operations, unlike human labor, which would gradually trade off quality.

Absence of Human Error

Even the most talented and brightest workers might cause a small amount of inaccuracy during the CNC machining process. Machines, on the other hand, are much more dependable and less likely to introduce flaws into the system. If anything, it is fascinating to notice that a repetitious operation becomes more error-prone when performed by a human over time, while becoming more efficient when performed by a machine over time. As a result, automation and CNC machines will reliably and consistently replicate goods with little mistakes.

Cost Reduction

It is common knowledge that automation lowers labor expenses. Additionally, it decreases the workforce, increases production overall, and enhances worker efficiency. Multiple machines can be managed, supervised, and controlled by one operator at once. As a result, businesses can complete the same task with fewer employees while still paying them fairly. CNC-driven automation lowers risks and avoids accidents, decreasing other liabilities in addition to the financial impact of wages, sick days, overtime, and other such benefits.

Enhanced Safety and Security

CNC machines can work independently and with little input thanks to automation. The only ongoing human engagement needed by the system after setup is routine maintenance. Even if changes need to be made to the program, sensors could still be used to input the changes remotely into the system. 1. You eliminate the health and safety dangers connected with exposing your staff to large machines by moving your labor off the floor. As a result, your workshop will be safer and have fewer accidents.

Operating Efficacy

Operational simplicity is introduced by a CNC machine since they are simpler to run and use. The initial setup and installation, followed by training, need the only work. Your staff will quickly be able to take use of the CNC machine once they understand its workings.

Collaborative robots are being deployed at the Danish manufacturing firm Trelleborg Sealing Solutions as more manageable and secure substitutes for conventional industrial robots. Each cobot has practically evolved into a CNC machine's auxiliary. Every time the company purchases a new machine, a robot is likewise ordered for it, as stated by Jasper Riis, the chief of production. This strategy is entirely acceptable and clearly highly successful for Trelleborg's objectives.

The company's machine operators can program the robots at a rudimentary level, but that appears to be the extent of their robotics education at this point. The operators' tasks have largely stayed the same as the machine tending they previously performed. The primary variation is one of scale. Each employee would previously tend to three, now tend 8.

More than just a popular trend, CNC automation is reshaping industries. It is clear from the above that the positives greatly exceed any drawbacks. On that basis, assess your machining needs and utilize the above benefits as a guide. Use the Robotiq CNC Machine Tending Solution Configurator to tailor a solution to your specific needs and contact our team to help implement your solution or stop by our Cobot Demo Day with your own parts to see the cobot in action.

Sources: https://forumautomation.com/t/advantages-and-disadvantages-of-using-cnc-automation-in-modern-machining/9998; https://robotiq.com/applications/machine-tending; https://www.universal-robots.com/case-stories/trel...